-

DA

Menu

Components

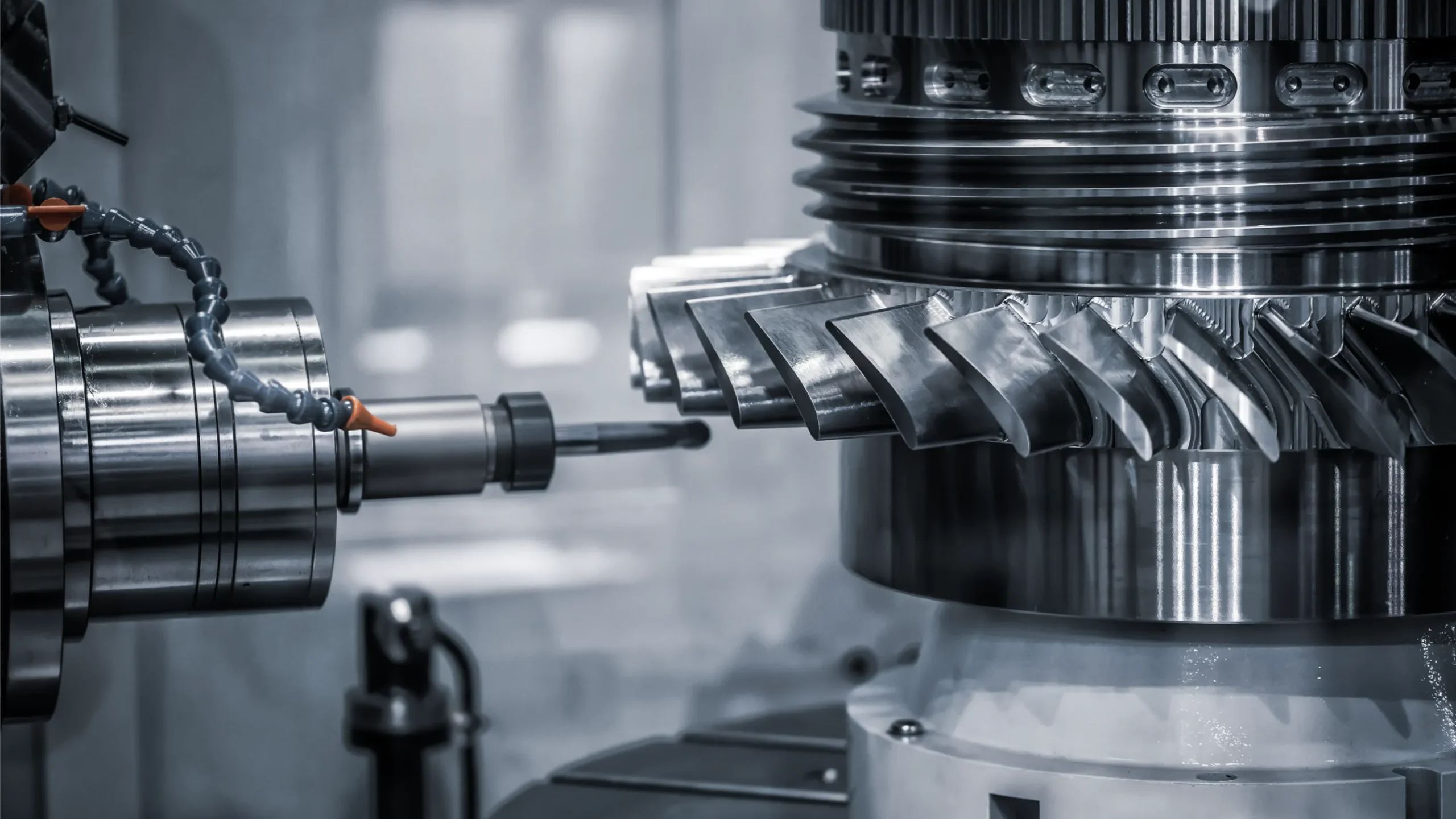

When manufacturing wind turbine components, CNC machining ensures precision that optimizes efficiency and extends the life of wind turbines, which is critical to the industry's profitability and sustainability.

The advanced capabilities of CNC technology enable the production of complex parts, tailored to the specific design requirements of wind turbines, supporting innovation in renewable energy.

If you have questions or need advice on the possibilities of CNC Milling, we are always open for dialog.

Materials

Used in wind turbine structures for its excellent weldability and high strength, making it ideal for towers and foundations. This high-strength low-alloy steel ensures reliability and longevity of the critical structures of wind turbines.

Suitable for manufacturing high-load wind turbine components, such as rotor shafts and gear parts. This alloy offers exceptional strength and fatigue resistance, which is essential for components that are constantly subjected to mechanical stress.

This high-quality aluminum alloy is used in parts where low weight and high strength are needed, such as blades and moving parts of wind turbines. The alloy's excellent strength-to-weight ratio and resistance to fatigue fractures support the efficiency and durability of wind turbines.

If you have questions or need advice, click here

Learn more about how CNC machining is used across different trades and industries.