Menu

CNC Denmark specializes in CNC milling technology. We provide customized solutions to our customers using advanced and innovative milling machines. Our expertise and dedication to quality ensures that we can produce precise products for a wide range of industrial needs. With a focus on innovation and reliability, we are your trusted partner in CNC milling technology, striving to fulfill your requirements with the highest standards of quality and precision.

CNC Denmark differentiates itself by not being limited by a specific type of CNC machine. We believe in having a wide selection of CNC machines to suit different needs and requirements from our customers. Our versatility in CNC machine technology allows us to cater to a wide range of projects and tasks, regardless of size, complexity or material.

CNC Milling

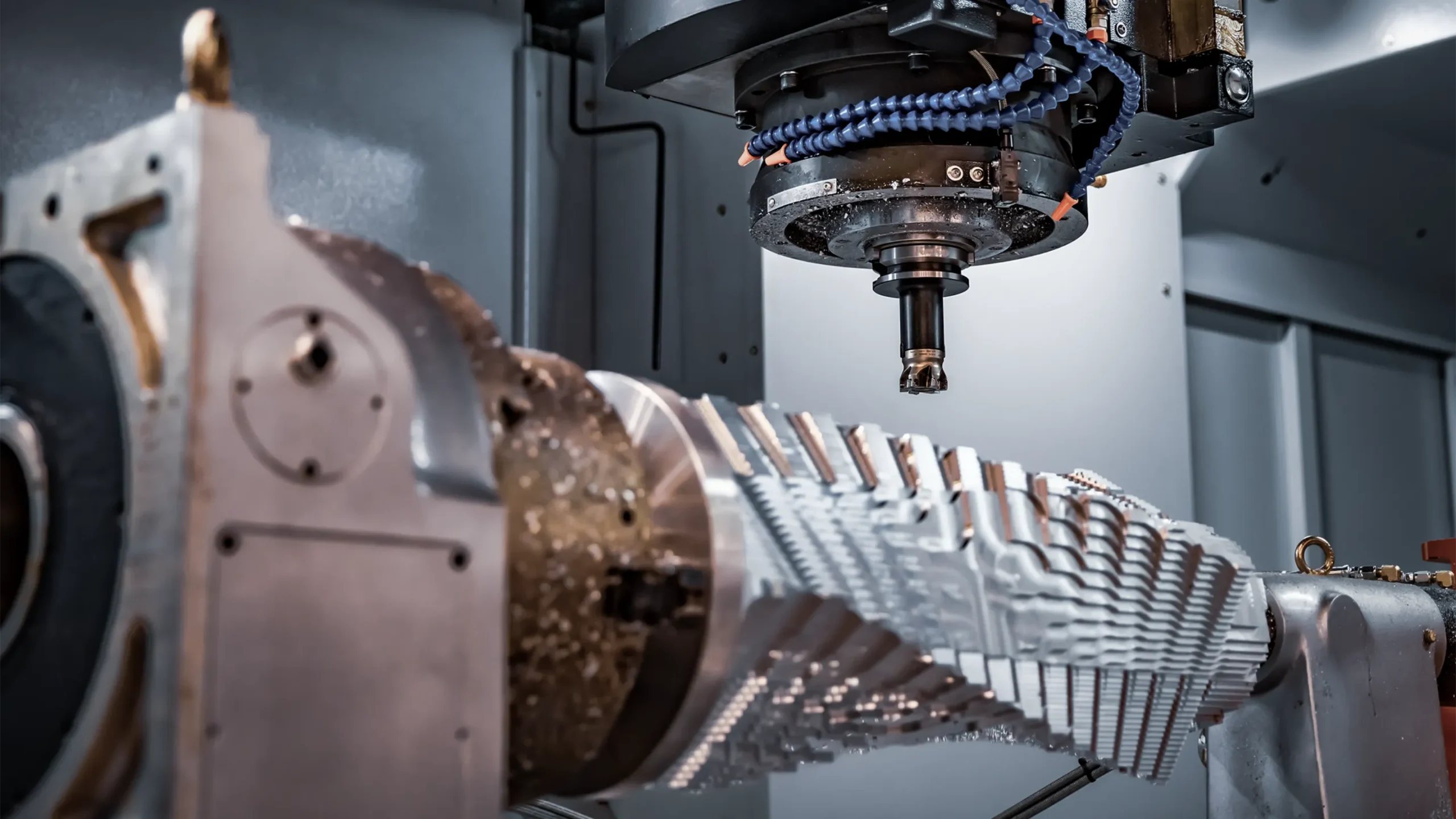

CNC milling is an advanced manufacturing method that uses computer-controlled machines to precisely cut and shape different materials.

At CNC Denmark, we offer a wide range of CNC milling services, covering everything from single part production to complete series production. →No matter the size or complexity of the project, we strive to deliver your orders on time, every time.

If you have questions or need advice on the possibilities of CNC Milling, we are always open for dialog.

CNC milling is a process where material is removed from a workpiece to create a part or component with a specific shape. This process is controlled by a computer that tells the machine exactly where to remove material using a rotating cutting tool. → CNC milling is a versatile and powerful machining method that is essential for modern manufacturing. Our role is to facilitate this process by matching your project's specific requirements with the optimal machining solution. From complex components to large series, we will find the right solution.

CNC stands for "Computer Numerical Control". This means that the milling machines are equipped with a computer that reads and executes design instructions from CAD files (Computer-Aided Design).

Unlike CNC turning, where the workpiece rotates, the cutting tool in a CNC router rotates while the workpiece is typically clamped still. The cutter can move in multiple directions - up and down, sideways and across - to cut at different angles and depths.

CNC milling is extremely versatile and can be used to produce complex geometries that cannot be made with CNC turning alone. It can make deep cuts, fine details and a variety of surface finishes.

A CNC router can work with a wide range of materials, including metals such as steel, aluminum, plastic and composite materials.

From small precision parts in watches to large components in airplanes, space shuttles and cars, CNC milling is used in a variety of industries, including aerospace, automotive, and healthcare.

It's a fast and efficient way to produce parts, often with very tight tolerances and high repeatability, which is essential for mass production.

If you have questions or need advice, click here

Learn more about how CNC machining is used across different trades and industries.

Get answers to the most common questions about CNC milling.

We have compiled a list of questions and answers to give you a deeper understanding of how CNC Denmark can assist with your CNC projects

Yes, CNC machining is very cost-effective, even for small batches, as it reduces material waste and optimizes production time.

CNC milling is a precise machining process where the material is machined using computer-controlled milling machines.

This differs from traditional methods by its high precision, ability to produce complex shapes and the efficiency it offers in the production of both small and large series.

Absolutely.

Our strength lies in our diverse network of partners, enabling us to work with a wide range of materials and complex designs.

We offer customized solutions tailored to your specific needs and unique project requirements.

We are committed to reducing the environmental impact of our machining processes.

We choose suppliers that use sustainable methods and materials, and we continuously work to improve our processes to minimize our ecological footprint.

At CNC Denmark, we understand the importance of on-time delivery.

Our extensive network and efficient workflows ensure that we can meet even the most time-critical projects without compromising on quality.

Starting a project with us is simple. Contact us with your ideas and requirements and our team will guide you through the entire process, from design to completion. We are committed to understanding your needs and work closely with you to ensure your project is a success.

We place great emphasis on quality and accuracy in all our projects.

Our quality assurance process includes strict control measures and collaboration with suppliers that meet our high standards.

This ensures that all finished products meet both our and your expectations.

Starting a project with us is simple.

Contact us with your project ideas and our team will work closely with you from start to finish.

We offer advice and support throughout the process to ensure your project is a success.

Get answers to any unanswered questions by contacting us

on phone +45 42 34 64 69 or send an email to info@cnc-denmark.com